Sludge Dewatering

Sludge Dewatering

-

-

R&D Results

More

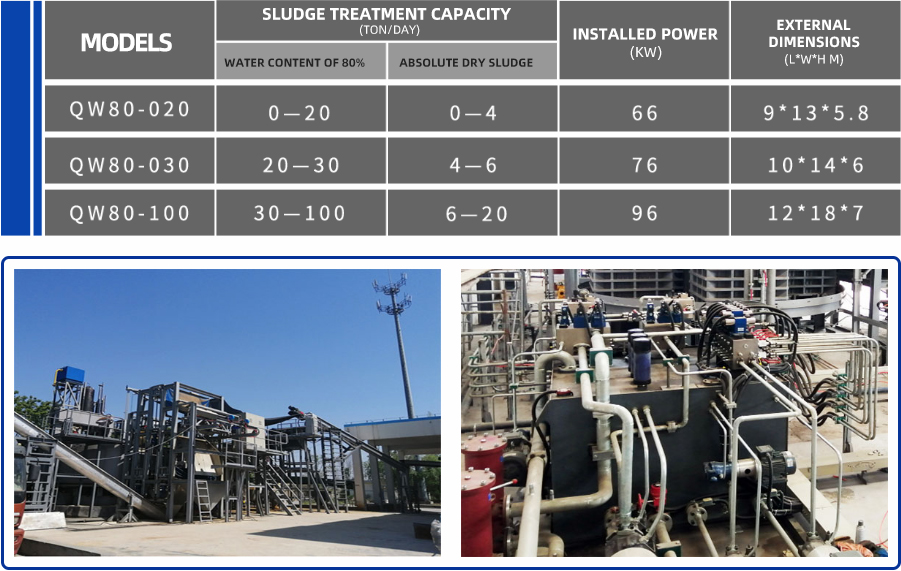

The ultra-high hydraulic dewatering system developed by Qingwu made significant improvements to the traditional diaphragm filter press, where its high-efficiency filter press and solid-liquid separation equipment provide higher pressures and efficiencies. This technology has now been partially patented, while national invention and utility model patents have also been filed. This technology represents a significant advancement in the field of sludge mechanical dewatering, overcoming the limitations of previous techniques that have struggled to reduce water content to a level below 60%. It has the potential to revolutionize the industry by enabling the reduction of sludge water content from 80% to below 50% through the use of filter press dewatering technology, a feat that has remained elusive until now.

Technology

- In-house Development of Mechanical Dewatering and Processing Technology for High Viscosity Materials

- Ultra-high Pressure Dewatering System Developed In-house, using purely physical and mechanical means of pressing and dewatering.

Process

Equipment

Sludge Fermentation

Sludge Fermentation

-

Advantages

The process entails the use of microbial high-temperature aerobic fermentation and rapid drying of sludge. The entire fermentation process can be completed in 7 to 9 days. The biothermal energy generated during the fermentation process can fully inactivate pathogens, viruses, parasite eggs and weed seeds, while simultaneously reducing the water content to below 30%. Furthermore, the sludge processed by our high-dry dewatering technology is free of lime powder and other additives, which can significantly reduce the likelihood of compost mixing and decrease the input. Consequently, this process is distinguished by a number of key characteristics, including a relatively small area of operation, a modest initial investment, a low operating cost, a brief processing time, and a high level of automation.

Technology

- Mastering aerobic fermentation technology with microbial high-temperature aerobic fermentation and rapid drying of sludge

-

Features

The rapid warming process, when combined with our high-temperature bacterial agent, allows the sludge in the tower to be heated to over 70 degrees Celsius within 48 hours and maintained at this temperature for an extended period. This method effectively eliminates a wide range of pathogenic bacteria and parasite eggs.

The rapid warming process, when combined with our high-temperature bacterial agent, allows the sludge in the tower to be heated to over 70 degrees Celsius within 48 hours and maintained at this temperature for an extended period. This method effectively eliminates a wide range of pathogenic bacteria and parasite eggs. The entire process happens in an enclosed space. Water and odour are collected and purified by the fermentation tower before being discharged.

The entire process happens in an enclosed space. Water and odour are collected and purified by the fermentation tower before being discharged. The reduction of sludge is a clear benefit of the low water content of the material in the tower. By using high-temperature bacterial agents for biological composting or drying processes, it is possible to add fewer or no additional auxiliary materials, which in turn allows for the real reduction of sludge.

The reduction of sludge is a clear benefit of the low water content of the material in the tower. By using high-temperature bacterial agents for biological composting or drying processes, it is possible to add fewer or no additional auxiliary materials, which in turn allows for the real reduction of sludge. Diversified uses. Since fewer or no additional auxiliary materials are added, the fermented sludge can be used for land use or fuel-blending incineration. This provides a new way for cities to solve the sludge problem.

Diversified uses. Since fewer or no additional auxiliary materials are added, the fermented sludge can be used for land use or fuel-blending incineration. This provides a new way for cities to solve the sludge problem.

Equipment